- PRODUCT SPECIFICATIONS

- PACKAGING

- Ask quotation

CEWELD® 316H exhibits corrosion resistance similar to matching, stabilized, austenitic 17Cr-12Ni-2Mo steels. It is specifically designed for high-temperature service (500-800°C) under long-term creep conditions.

CEWELD 316H is intended for welding: Steam pipelines and superheater headers, Furnace parts, Specific gas and steam turbine components, Applications in the petrochemical industry, Fossil-fuelled and nuclear power plants.

CEWELD® 316H exhibits corrosion resistance similar to matching, stabilized, austenitic 17Cr-12Ni-2Mo steels. It is specifically designed for high-temperature service (500-800°C) under long-term creep conditions.

CEWELD 316H is intended for welding: Steam pipelines and superheater headers, Furnace parts, Specific gas and steam turbine components, Applications in the petrochemical industry, Fossil-fuelled and nuclear power plants.

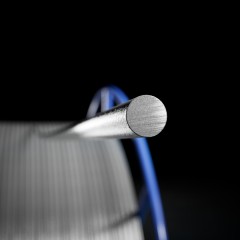

CEWELD® 316H is designed for welding austenitic 316/316H steels at high temperatures (500-800°C) under long-term creep conditions. This filler metal can also be used for welding 321/321H and 347/347H in high-temperature applications. This is particularly important for thick, highly restrained weld joints, as the risk of premature failure due to intergranular HAZ (Heat Affected Zone) cracking is reduced by using more ductile weld metal instead of 347H.

ISO 15608: 8.1 Austenitic ≤ 19 % Cr

1.4401, 1.4404 , 1.4409 , 1.4429, 1.4432, 1.4435, 1.4436, 1.4571, 1.4580, 1.4583, 1.4919

X5CrNiMo17-12-2, X2CrNiMo17-12-2, GX2CrNiMo19-11-2, X2CrNiMoN17-12-3, X2CrNiMo17-12-3, X2CrNiMo18-14-3, X3CrNiMo17-12-3, X6CrNiMoTi17-12-2, X6CrNiMoNb17-12-2, X10CrNiMoNb18-12

UNS S31600, S31603, S31635, S31640, S31653

AISI 316L, 316Ti, 316Cb, 347, 347H, 321, 321H, CF10M, BS 316S51, 316S52, 316S53, 316C16, 316C71

| Heat Treatment |

RP0,2 (MPa) |

Rm (MPa) |

A5 (%) |

Hardness |

|---|---|---|---|---|

| As Welded | 450 | 650 | 35 | HRc |